Shangcon intelligent to customer needs as the starting point, to provide customers with a full range of solutions.

CEMS flue gas on-line monitoring system is suitable for on-line real-time monitoring of gas dust concentration in high temperature, high humidity and high corrosive flue environment. It has the advantages of high measurement accuracy, good stability, modular structure, simple operation and convenient operation and maintenance. Products through CE/FCC certification, performance comparable to similar international products.

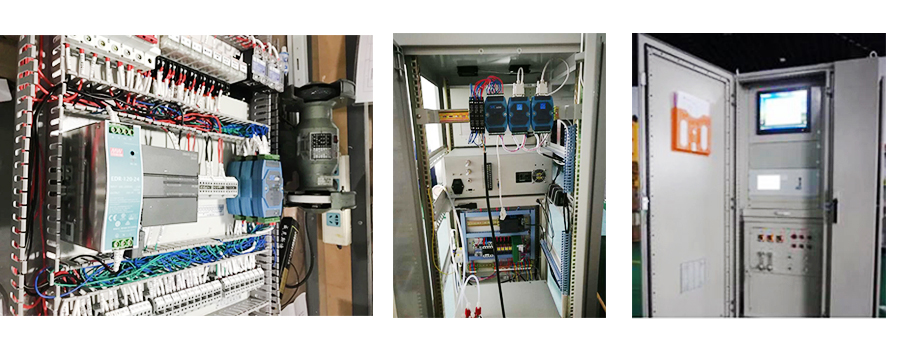

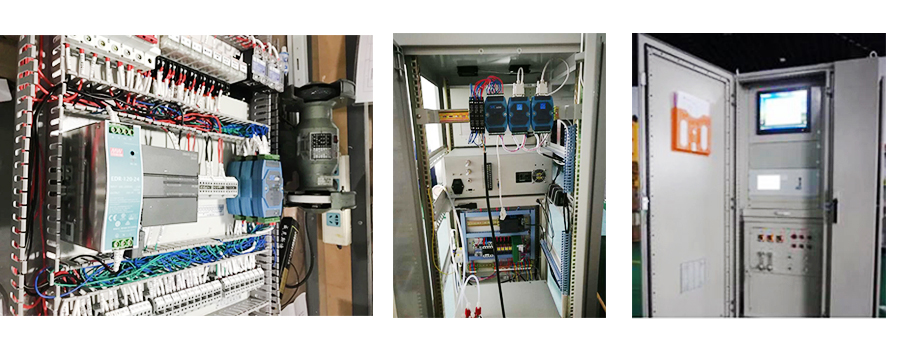

The solution uses an overhead tablet computer, which is easy to install in a 19-inch cabinet. 15-inch or 17-inch LCD, 1280*1024 resolution, 5-wire industrial resistance touch screen. Equipped with Intel® Celeron® J1900 CPU, it contains 4 USB2.0, 2USB3.0, 6 COM ports, 2 Ethernet ports, and all I/O ports are anti-surge design, which is very suitable for continuous operation in harsh electromagnetic environments. Module S-7017A+, S-7024 measuring range 4-20mA or 1-5V, high measurement and control accuracy, strong anti-interference ability, easy installation, simple debugging. The module is connected to the COM port of Siemens S7-200PLC through RS485 bus. PLC reads and writes module data through simple MODBUS instruction, which has higher accuracy and lower cost than PLC expansion module. This scheme achieves the optimal cost performance, which is better than direct use of Siemens I/O module. At the same time, the combination is easy to expand, and other S-7000 modules can be added as required. Customers can also customize S-7000 series modules according to their needs by using sicstm_7000_Utility debugging software developed by Shangcon.

The S-7000 series 485 remote I/O module is complete. Includes analog input/output, digital input/output, digital input/relay output and count/frequency specifications. With 3000V isolation protection, wide voltage input, long communication distance, simple wiring, easy installation and other features, and fully supports ASCLL and Modbus/RTU two communication protocols, easy to integrate with other equipment and software.

Advantages and characteristics of CEMS flue gas on-line analysis system:

-

?Independent core technology and rigorous environmental testing ensure industry-leading sensitivity and stability

-

?The forward scattering principle based on soot particles has extremely high sensitivity and resolution, and can continuously measure ultra-low concentration soot particles on line

-

?Using the adaptive grading method, it is also possible to measure the field measurement of high particle concentration with a wide dynamic range

-

?Through sampling tube heating and measuring chamber heating design, it can be used in cases where the measured gas contains extremely high humidity

-

?Equivelocity sampling module can dynamically track flue gas velocity

-

?It can be used for real-time continuous measurement of particle pollutant concentration of various pollution emission sources, which can be supported by CEMS system, or a single or several units can be continuously connected to a set of soot monitoring network, sharing a single platform.

-

?All devices have standard 4-20 signal outputs for easy expansion

-

?Multifunctional, can do both monitoring and control

-

?The data format of the report complies with Chinese environmental standards

Technical parameters of modules and tablets:

-

?Module: 8-channel voltage and current acquisition module

-

?16-bit resolution

-

?8 differential channels

-

?10, 100 times/second sampling rate

-

?Supports independent channel Settings

-

?3000VDC isolation voltage

-

?Support ASCLL code, MODBUS RTU communication protocol

-

?Operating voltage +10V~+48V DC

-

?Operating temperature -40℃~85℃

Tablet computer

-

?1280*1024 resolution LCD LCD display

-

?High temperature five-wire resistive touch screen

-

?Operating temperature 0~+60℃

-

?Support wall-mounted, embedded, overhead mounting

-

?CE/FCC International certification

-

?The USB2.0 extension interface is provided on the panel

-

?Front panel IP65 protection rating

-

?Meet EMI/EMC standards, anti-electromagnetic interference internal structure design

-

?ESD contact 8KV, air 15KV

Customer field application: