Shangcon intelligent to customer needs as the starting point, to provide customers with a full range of solutions.

With the development of the current building materials industry, safety glass has attracted more and more attention. The main raw material of safety glass is tempered glass, and the glass tempered unit produced by a glass factory in Hebei Province is a unit that processes flat glass into tempered glass. The main principle of this unit is to first heat the glass to a certain temperature, and then quenching. In the production process of tempered glass, the biggest impact on product quality is how to make the glass form a large and uniform internal stress. The biggest impact on the yield is how to prevent cracking and deformation. No matter which of the above influencing factors are closely related to the heating and cooling conditions of the glass, the accurate and timely collection of the temperature in the unit furnace plays a crucial role in controlling the temperature.

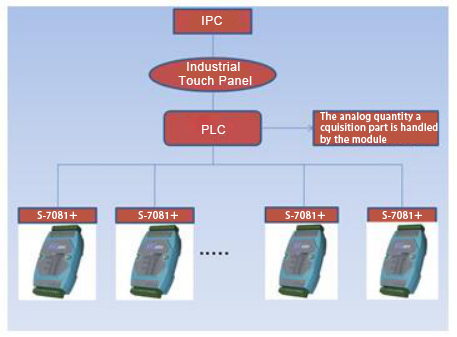

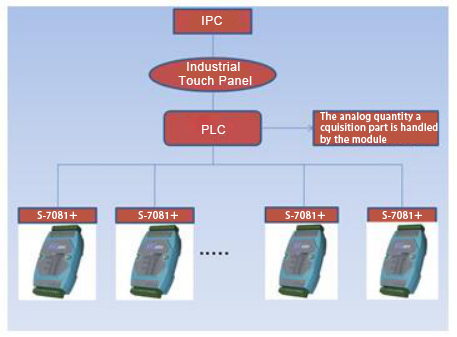

System diagram:

System composition

The system is composed of touch screen, industrial computer, PLC and S-7018+ thermocouple acquisition module.

As a human-computer interaction system, the touch screen can set, access, display process parameters and can set and display temperature;

Industrial computer as the host, complete the data display and storage, PLC to complete the entire process and temperature control, and S-7018+ replaced the original PLC analog acquisition part, greatly reducing the cost.

Each glass tempering furnace according to the daily amount of different, temperature measurement points range from 70-300 points, the number of S-7018+ modules range from 10-40, as a PLC analog quantity acquisition module, responsible for temperature acquisition in each area.

The S-7018+ is an 8-channel analog calorimetric thermocouple input module. The resolution is 16 bits, and the thermocouple types are J, K, T, E, R, S, and B can be flexibly set.

As the S-7018+ temperature acquisition module adopts RS-485 communication mode, it can be long-distance communication, and all modules of the system only need to be connected by one communication line. It has high communication rate, high sampling resolution, intelligent, photoelectric isolation, strong anti-interference and dual watchdog design, which enhances the reliability of the system and makes high-speed data I/O possible. Support standard MODBUS protocol, can be seamlessly connected with PLC, software development is very simple.

The system can increase or decrease the number of modules according to the measured temperature points, the configuration is flexible, the terminal can be pluggable, the guide rail installation, the construction and maintenance is convenient.